Spindle orientation is more often called within cycles (automatically) or during setup (manually), but it is also available under program control via M19. It is not unusual for specific machine models to have such combined commands, which make for shorter, more quickly written programs. This one M-code does the work of both M03 and M08. Spindle on (clockwise rotation) and coolant on (flood) They are used in training classes for operators, both on-site and remotely (e.g., Tooling University).įor machining centers with pallet changers These concepts are taught in textbooks such as Smid, and online multimedia (videos, simulators, etc.) all of these teaching resources are usually paywalled to pay back the costs of their development.

To understand how the T address works and how it interacts (or not) with M06, one must study the various methods, such as lathe turret programming, ATC fixed tool selection, ATC random memory tool selection, the concept of “next tool waiting”, and empty tools. Many lathes do not use M06 because the T address itself indexes the turret.Programming on any particular machine tool requires knowing which method that machine uses. The M03 direction is always M03 regardless of local vantage point and local CW/CCW distinction. The right-hand rule can be used to determine which direction is clockwise and which direction is counter-clockwise.Right-hand-helix screws moving in the tightening direction (and right-hand-helix flutes spinning in the cutting direction) are defined as moving in the M03 direction, and are labeled “clockwise” by convention. The speed of the spindle is determined by the address S, in either revolutions per minute ( G97 mode default) or surface feet per minute or meters per minute ( G96 mode under either G20 or G21).

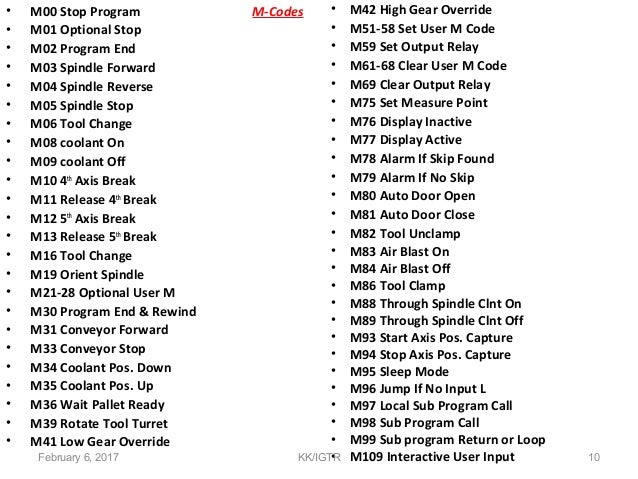

No return to program top may or may not reset register values. Machine will only stop at M01 if operator has pushed the optional stop button.

Non-optional-machine will always stop upon reaching M00 in the program execution.

0 kommentar(er)

0 kommentar(er)